|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

home needs local resources comfort safety and health contact |

Back

Design Process

Mechanical DesignFor all practical purposes the stove is a mechanically simple device. As such this section will not be elaborate. This section concerns certain aspects concerned with safety, maintenance and production. Five aspects are covered.

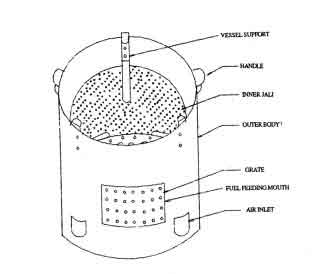

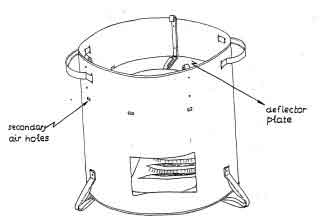

SafetyOn the average the heavy multiple pan mud stoves have no problem on the stability count. The problem is fairly severe with the single pan metal stove which has been so far made with recycled metal sheets in most countries of Africa. These look extremely flimsy. In our sketches of stove designs various forms of supports have been shown already. We will not repeat them here. In particular the single pan chimney stove is very vulnerable. This is one of the extra reason for the short chimney chosen for the chimney Maisauki. This is also the reason to choose in this design the broad stove body in spite of the combustion chamber being smaller. It is useful to adopt similar tactics for chimneyless stoves.(see for example the Tara Stove of the Development Alternatives in India; Fig.2; Gusain 1990).The next important item is the pan support. The main issue here is simply that the pan needs to sit firmly on its support. This is essential for preparation of foods like ragimudde, tuo and ugali. Vigorous stirring is involved in the preparation of such foods. (see Figure 3). Some typical supports can already be seen in the earlier sketches. An additional one designed by Sielcken for use in Ethiopia are shown in Fig. 4. This stove also has a broad base, but provides a de ector plate which produces a compact ame as well as a convenient support for pans of di erent sizes. Note that the legs in this stove make the stove much more stable. Again the multi pan mud stove seems to score on this point.  Fig.1. The Tara Stove. Source: Gusain (1990) However many field studies have established two features of such stoves. The pan supports wear out very fast. In addition the bridge between the two pans is a vulnerable point. The original Astra stove had metal reinforcements in the bridge region that makes the design more robust. A suggestion to overcome this difficulty is to use a prefabricated top plate. Three alternatives have been used so far. The rstone is dueto Micuta who recommends a castiron plate (1985). The second option is a cast mud plate (Nada Chula; Sarin 1985). The final one is to use a ceramic top (Astra Stove; Kumar et al.1990). MaintenanceNext point concerns features that have to be incorporated into the design for easy maintenance. The first of these is the ash tray that can be removed, the ash cleared, cleaned and refitted. Next concerns the maintenance of the chimney. In most designs the debris from cleaning the chimney falls in some part of the stove. Obviously this requires removal and thus the part where it falls should be easily accessible. A door/removable brick has to be incorporated at an appropriate location. Needless some type of brush with Fig.2. Ragi making in Ungra, India. Source: Geller(1983)  Fig.3. Stove ADD2 for use in Ethiopia. Source Sielcken (1985)

a sufficiently long handle for carrying out this activity would be required. Especially with chimney cleaning the user needs two instructions: (i)how frequently should the chimney be cleaned? and (b) who will do it? The former is an engineering question, but alas without a precise answer at this moment. Households with central heating systems in Europe, that use mostly gas, have their chimneys cleaned once a year. Noting the vast di erence that exists in cleanliness of burning of gas and wood, it seems that the chimneys of wood stoves need cleaning at least once in six months. Life-timeThe life-time of a stove is strongly related to the materials used to fabricate the di erent parts of a stove. All the three material classes that we covered in Table 10.2 have limitations from this point of view. There are no simple calculation methods that are able to predict the life-times of a stove. The only approach one has is to survey the stoves in use on a more or less regular basis. Current surveys are all what one might call snapshot surveys carried at one point of time. In general this is an expensive business. Most of the surveys available (see for example Joseph et al., 1990) use very small samples and generalizations on such meagre data base seems rash. As an example we quote some results about Mai Sauki again. Tables 10.17, 10.18 and 10.19 show the condition of the Mai Sauki as a function of time, provide a summary of the observed defects and the % of defects as a function of the size of the stove respectively (Bussmann 1988). Using the life-time model of the previous sections and the results of Table 10.17, the average life-time of Mai Sauki is derived as 16 months. This is claimed to be 33% longer than the life-time of the traditional Malgache stove. This difference, in spite of being made with the same thickness steel plate, is caused by the

Table 1 shows that the grate is the most vulnerable part. The alternatives to the present construction are to use thicker gauge sheet, a cast iron grate or even ceramic grates. Most of these options have a price tag associated with them. Of course the role of grate in assisting combustion and thermal performance is not so well established. For example Figure 5 shows that the variation in grate porosity has negligible in uence on the efficiency of the stove. We could have anticipated the result since in the Mai Sauki a large amount of air gets through the fuel loading port. Swosthi does not use a grate, but yet produces efficiencies of the order of 40%. Thus one could do away with the grate until such time we understand its role better. Finally Table 2 shows that the percentage of defects increases with the size of the stove. This is to be expected since the larger stoves are subjected to heavier loads, but are made out of the same materials. There appears to be a clear pay-o between life-time and the materials used. Of course there is also a limitation in the data set -there are very few large stoves in the sample. Thus one should treat the conclusion above with caution. Production Design.Manufacturing |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||